It started as a Word document, pecked out letter by letter at a dining room table in Connecticut.

Now, it is 150,000 copies of a 626-page book called “Moon Witch, Spider King,” with a luminous cover that glows with neon pinks and greens.

While digital media completely upended industries like music, movies and newspapers, most publishers and authors still make the bulk of their money from selling bound stacks of paper.

Here, we will show you how vats of ink and 800-pound rolls of paper become a printed book.

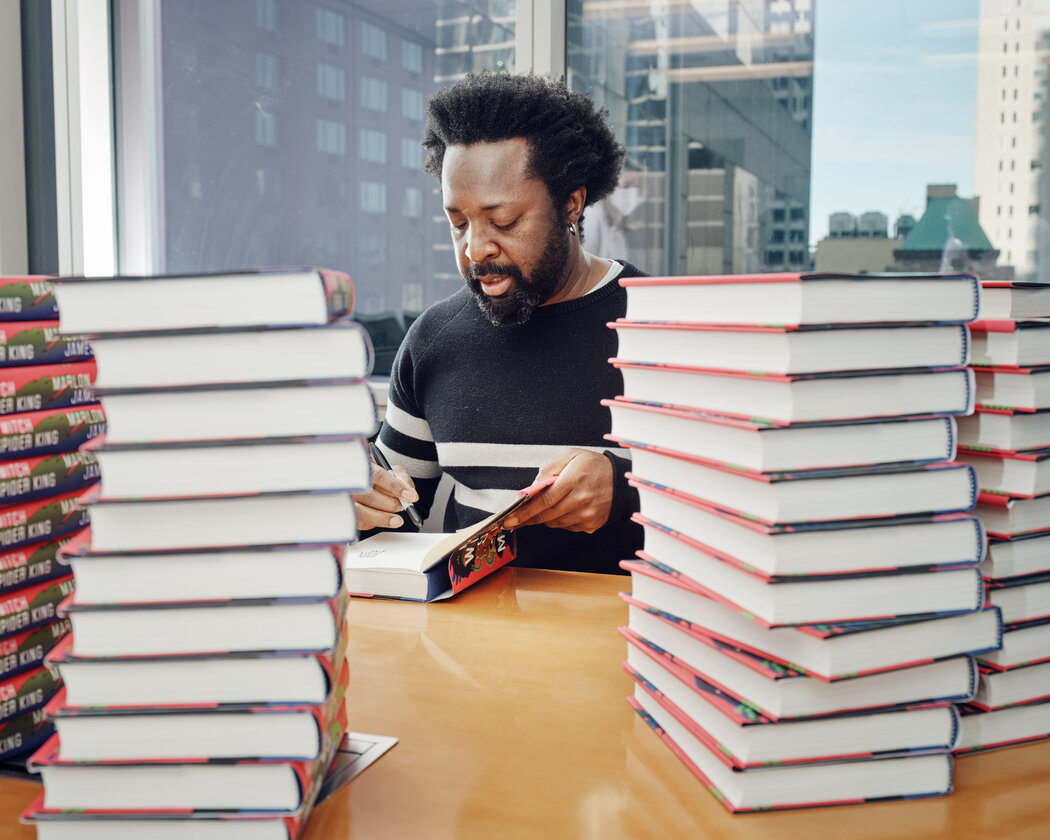

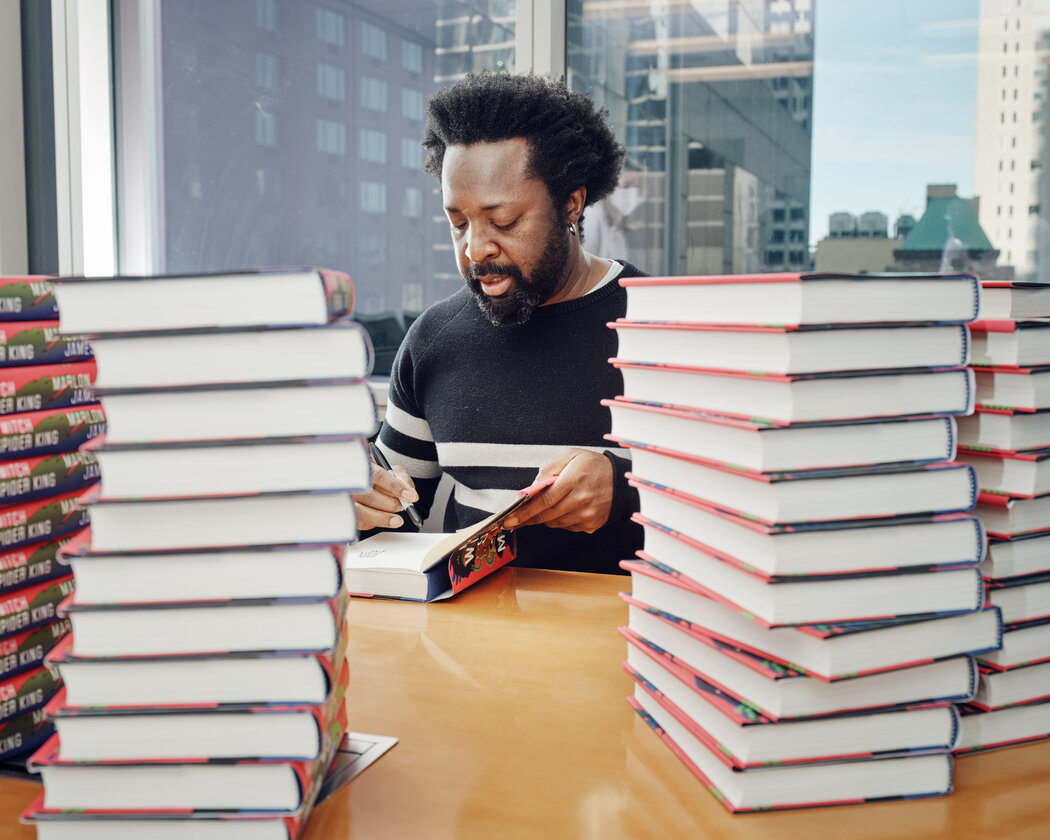

The title we will follow on its journey is “Moon Witch, Spider King,” a fantastical epic that draws on African mythology, the second book in a trilogy by Marlon James.

Let’s watch this book get born.

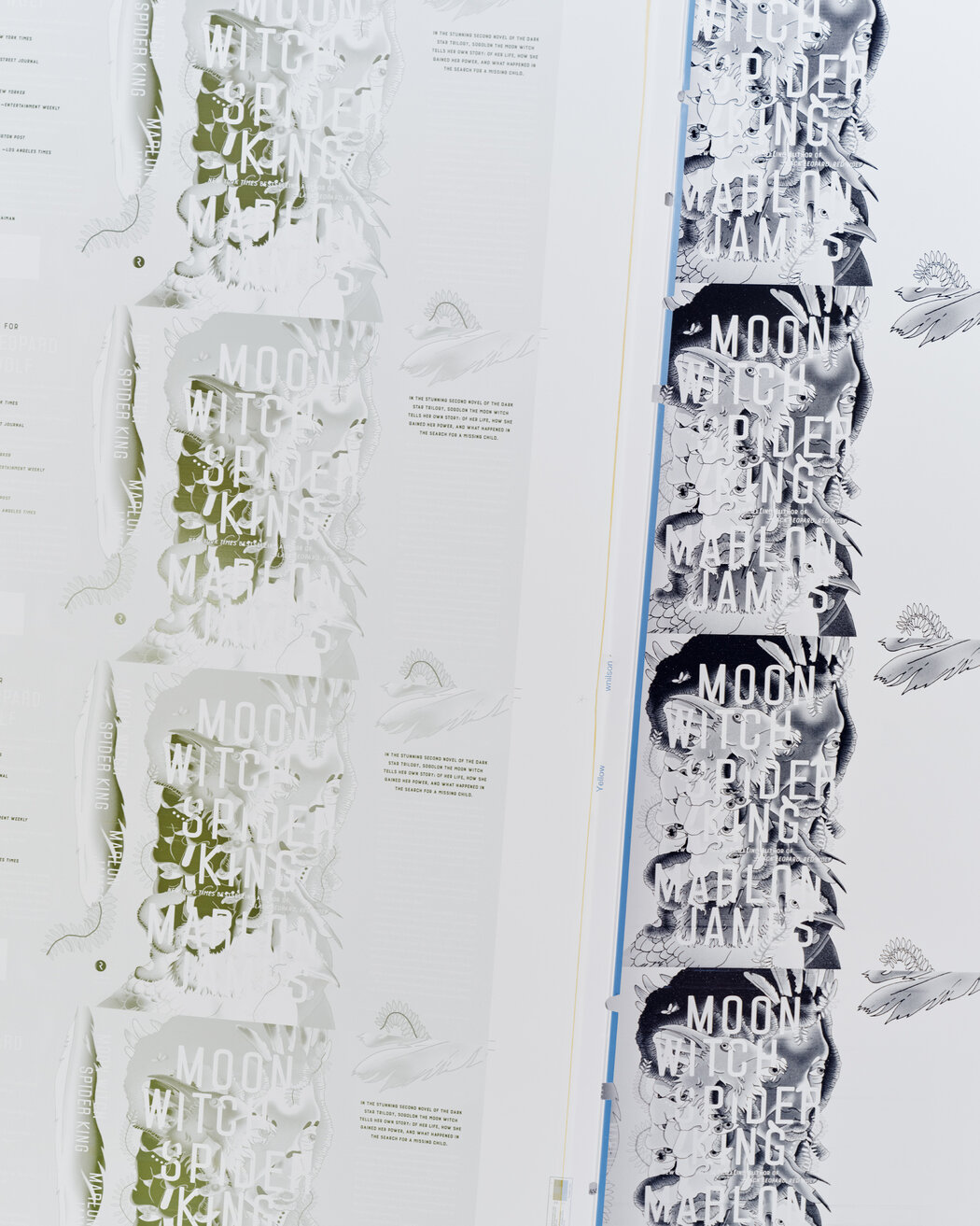

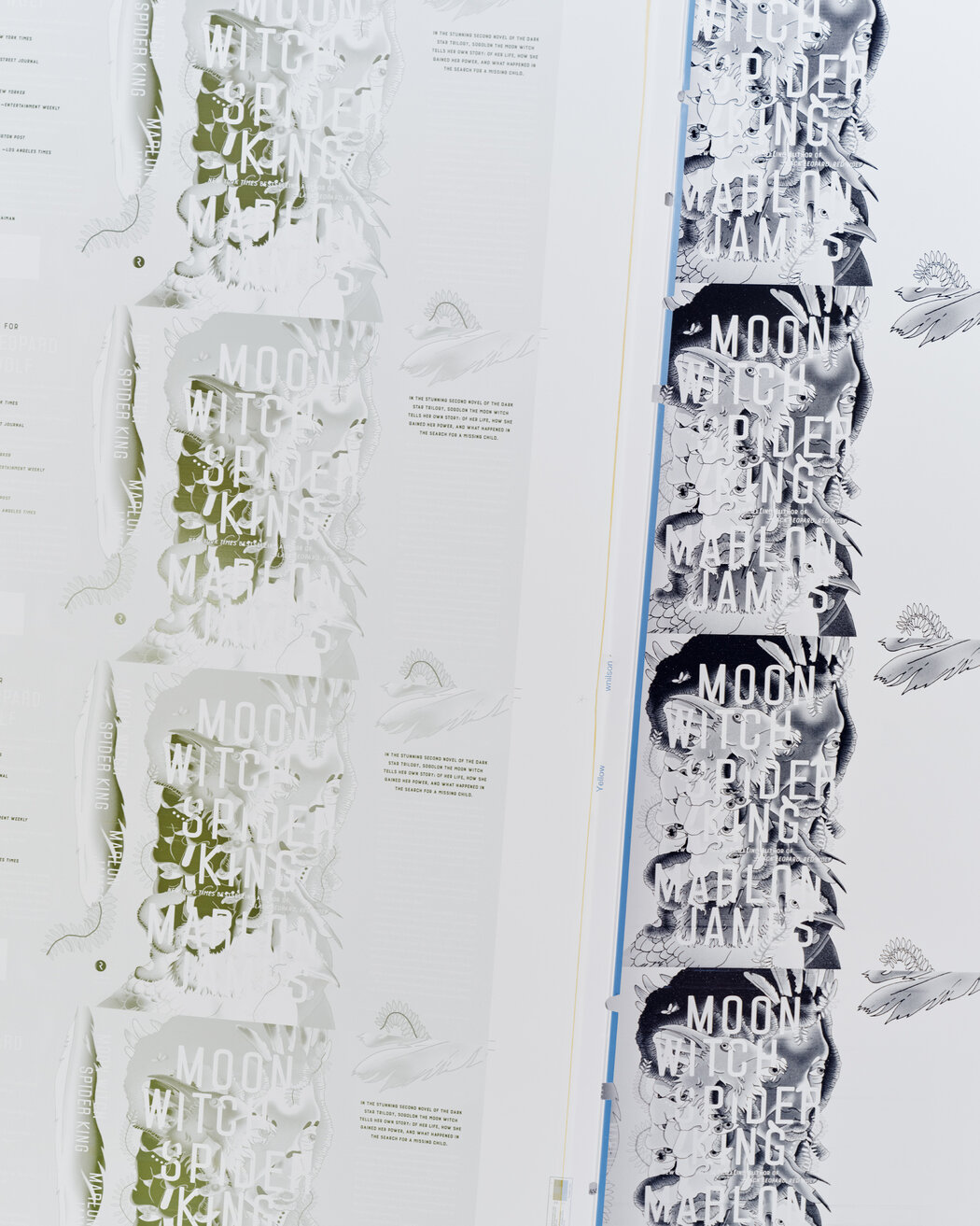

The book jacket was manufactured first. The cover of “Moon Witch, Spider King,” printed at Coral Graphics Services in Hicksville, N.Y., was unusually complicated, with a vivid mix of bright colors. James, who used to be a graphic designer, joked that his previous profession — and accompanying opinions — made him “the worst type of person” to consult on the cover.

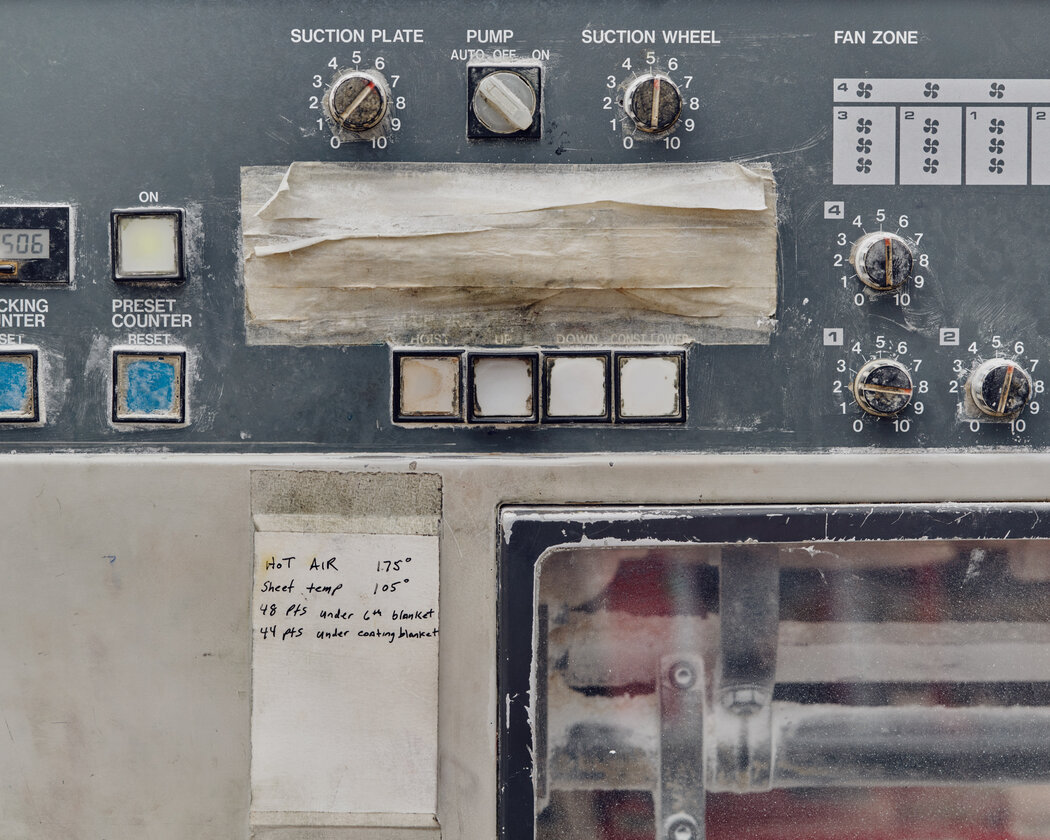

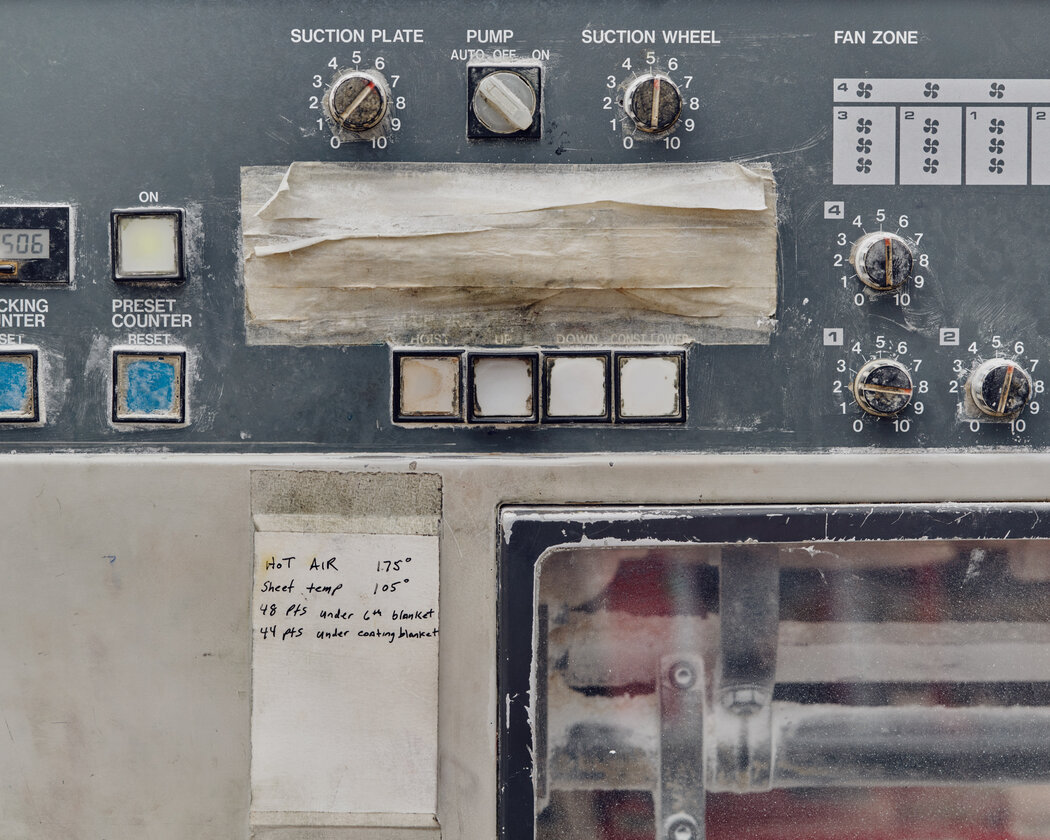

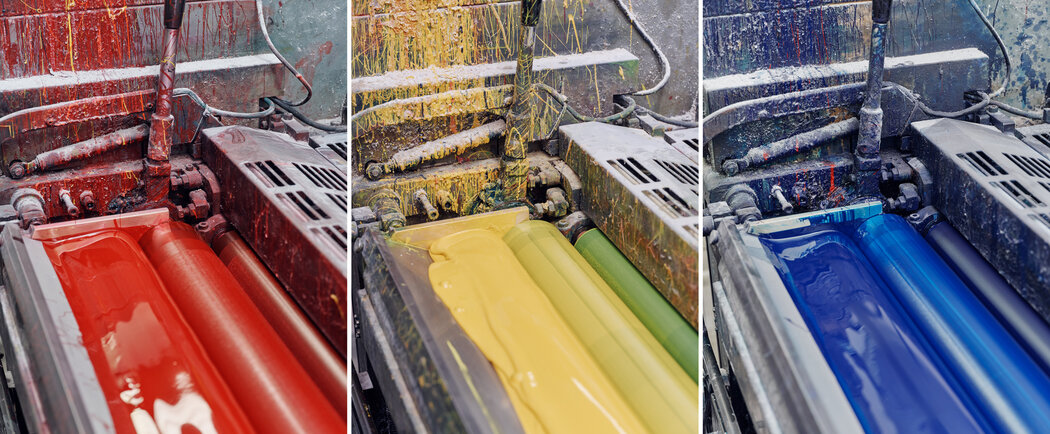

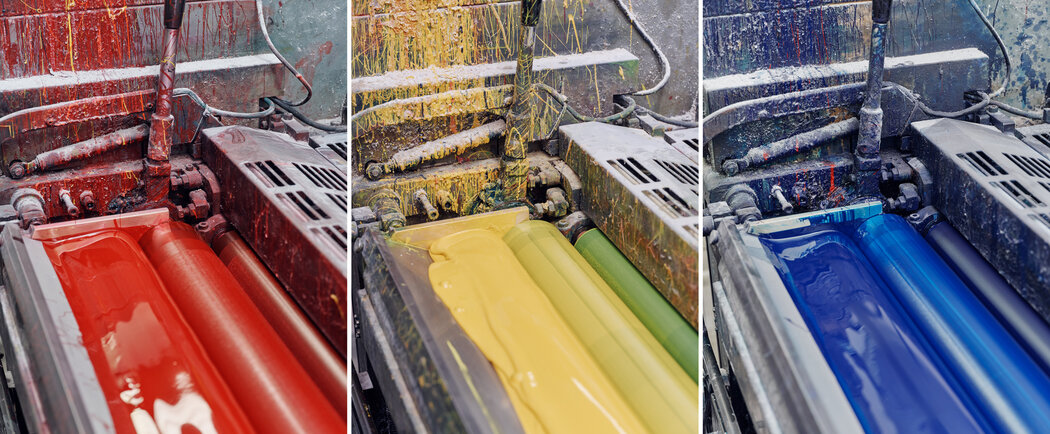

Most covers are printed using black, cyan, magenta and yellow ink, but two additional colors were used to print this one: Day-Glo green and a special blue. The machine above is loaded with 8,000 sheets of paper at a time, which are then fed through the press. Each section of the machine contains a separate tank of ink, one for each color.

Thomas Prior for The New York Times

These are control knobs on the six-color press. The “fan zone” controls regulate the air that is blown onto the paper.

Thomas Prior for The New York Times

A pressman, Glenn McCarthy, checks the plates and the ink levels in the proofing stage. He’s covered with a fine white dust called Spray Powder, which is used to keep the ink from bleeding.

Thomas Prior for The New York Times

Both the humidity and the temperature of the plant are important. The press area is kept around 70 degrees, and to keep the air moist, a fan blows a constant fine mist of water.

A press operator, Sal Peri, checks a proof before the print run begins.

Thomas Prior for The New York Times

About 800 different colors are stored in the ink room. Coral Graphics goes through approximately 2,500 pounds of ink every month.

Taps of ink are connected to 440-pound drums of the four main printing colors.

Thomas Prior for The New York Times

Full ink tanks ready to print.

Used yellow and black plates.

Thomas Prior for The New York Times

McCarthy stands near the color viewing stations, where he is responsible for adjusting the ink throughout the print run to make sure the colors are just right.

A stack of 40,000 printed covers waits to be laminated, which makes them more durable. On the right are rolls of laminate.

After the covers are laminated, they are loaded onto a truck and driven to a plant in Virginia that will print the book and package them all together.

The book itself was printed by Lakeside Book Company, one of the largest printing companies in the United States, at their 690,000-square-foot facility in Harrisonburg, Va. It runs 24 hours a day, seven days a week, and prints millions of books each week.

Thomas Prior for The New York Times

Plates of text hang, ready for their turn in the press.

Thomas Prior for The New York Times

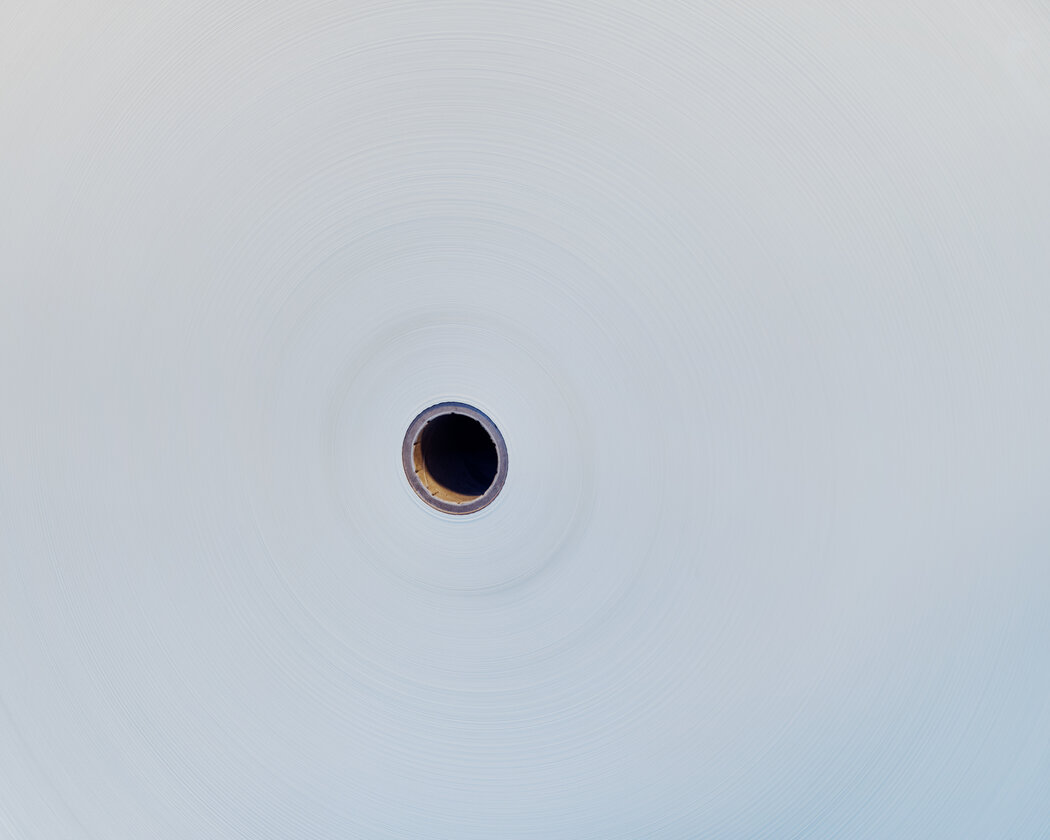

These giant rolls of paper have been lined up for a day of printing. The press itself is a goliath: It is 26 feet wide and 127 feet long, and weighs about 200,000 pounds. According to Lakeside, you could park six semi trucks in that machine, and it would take all six of those trucks to move it.

Thomas Prior for The New York Times

A roll of paper sits waiting to be spliced and spooled into the press.

Thomas Prior for The New York Times

On the left, press assistants can access the areas where the plates are hung. On the right is where ink pumps into the press.

Thomas Prior for The New York Times

Rolls of paper weigh about 800 pounds each.

Thomas Prior for The New York Times

Gaby Gomes, a press assistant, changes one of the plates. The book is printed 32 pages at a time, and every few hours, a worker must swap out the plates so the next 32 pages can be printed.

Scoop Video

One of the many rollers in the printing press.

Thomas Prior for The New York Times

At this station, the pressmen can check how the ink is laying on the paper using a densitometer, the blue tool at the center that looks a little like a walkie-talkie, and can then make needed adjustments using the ink controls.

Thomas Prior for The New York Times

Paper moves through the giant press.

Scoop Video

At the end of the printing press, the 32-page sections are cut and folded before heading down this conveyor belt.

Thomas Prior for The New York Times

Thomas Prior for The New York Times

The printed sections are then bundled together to keep them in place until they are bound. These bundle boards are placed at either end to keep the sections tidy and in the proper order.

Scoop Video

A stack of 32-page sections is lowered onto a bundle board. When the pile reaches a weight of about 30 pounds, another board is placed on top. Wrapped up as a unit, the stack then heads to the bindery.

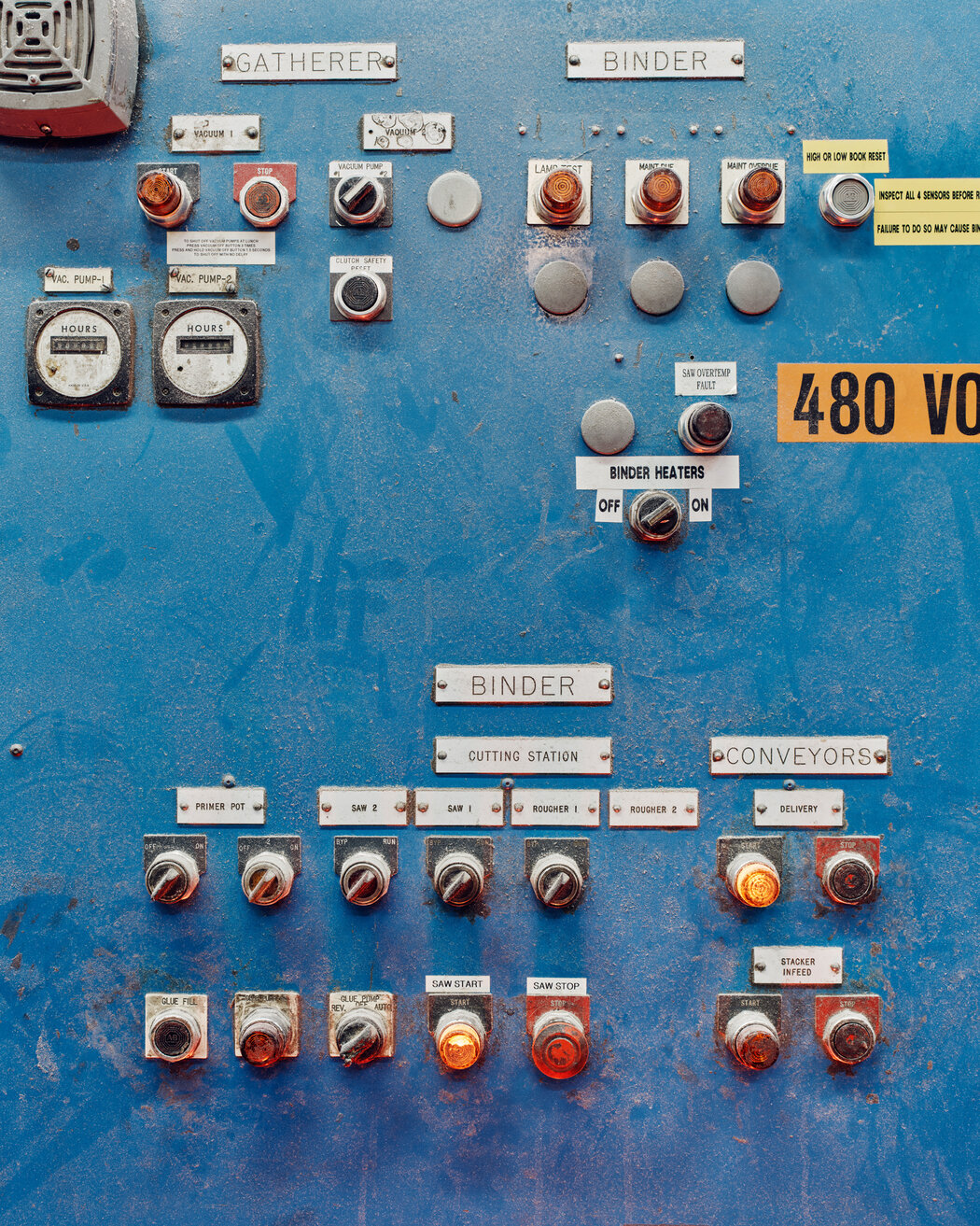

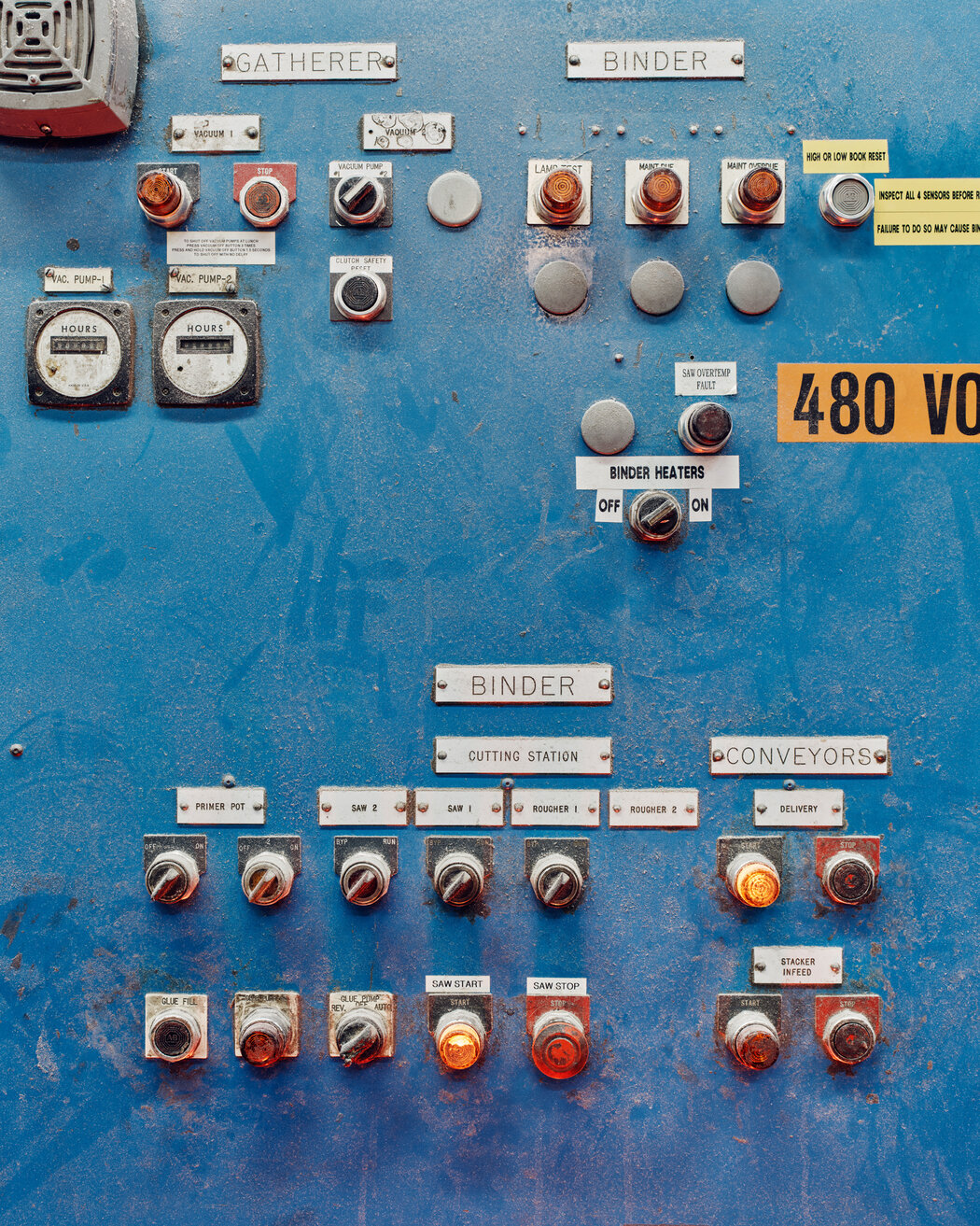

In a separate area of the Lakeside plant, the books come together: The printed pages get bound, glued into cardboard covers and jacketed.

The pages of “Moon Witch, Spider King” sit on pallets in the binding area before they’re loaded into the gathering machine. That machine will put the pages in order, arranging them as a complete piece for the first time.

Pages are fed into the gathering machine.

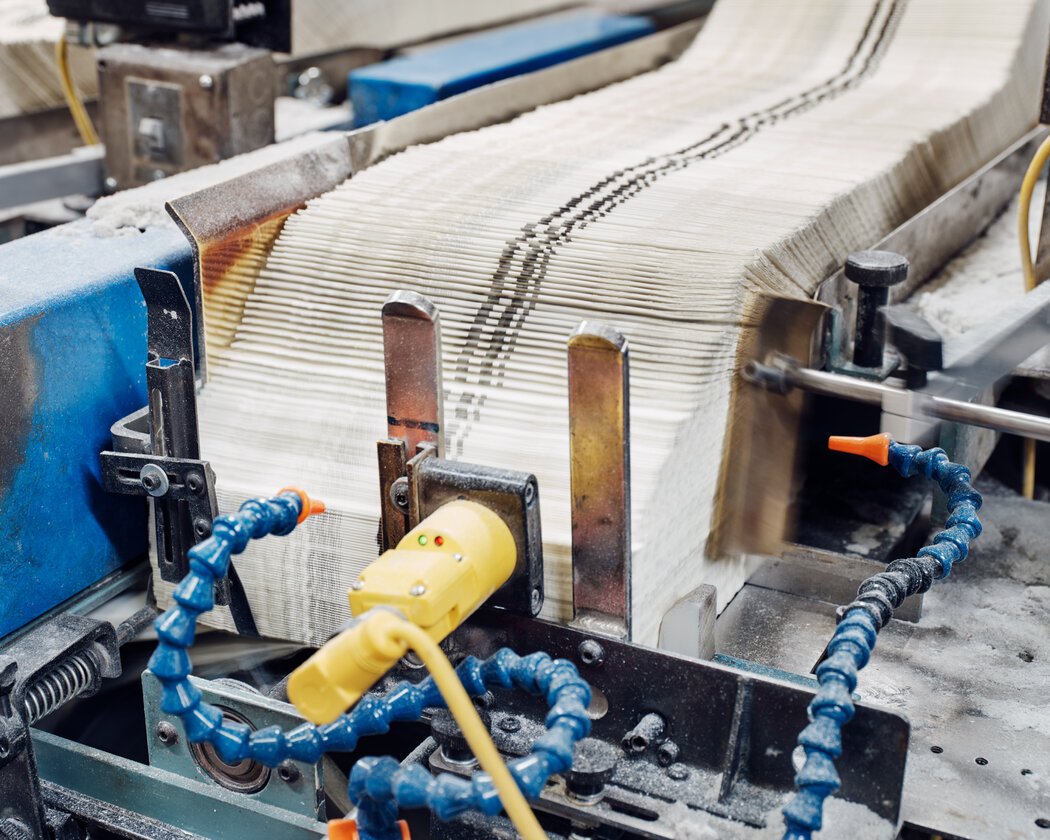

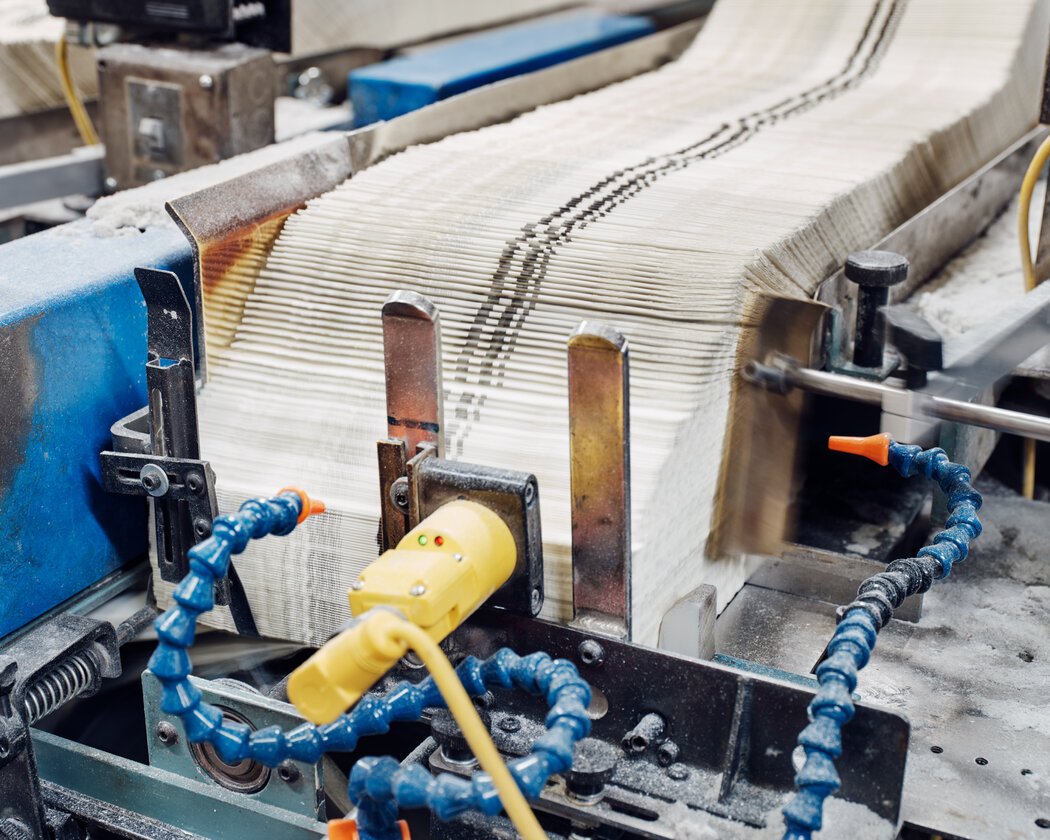

Each book is trimmed and then glued together in the binder.

Scoop Video

This conveyor belt carries bound books away from the binder. If one leg of the process goes down, this conveyor automatically sends all the books to the other side, allowing the process to continue while repairs are made.

Thomas Prior for The New York Times

The binding process uses a tremendous amount of glue.

After the books are bound and glued, they head to a machine called the backer, which readies the book for the cardboard cover to be attached.

The cardboard cover is called the “case,” and the machine that attaches it the “case-in.” Mitch Strickler, a case-in operator, stands at one of his stations where he checks that the cases are being applied correctly.

Printed and cut covers wait on pallets.

Scoop Video

Covers are separated and stacked before going into the jacket wrapper machine.

Boxed copies of “Moon Witch, Spider King” are ready to be sent to the distributor.

“Moon Witch, Spider King” is Marlon James’s fifth published book, but he says, “There is still something miraculous about a book, about seeing it. It took me so long to find a publisher when I was starting out, you know. Just the fact of a printed book is something that I don’t think I’ll ever get over.”

James signs copies of his new book at the Penguin Random House offices in Manhattan.

Scoop Video